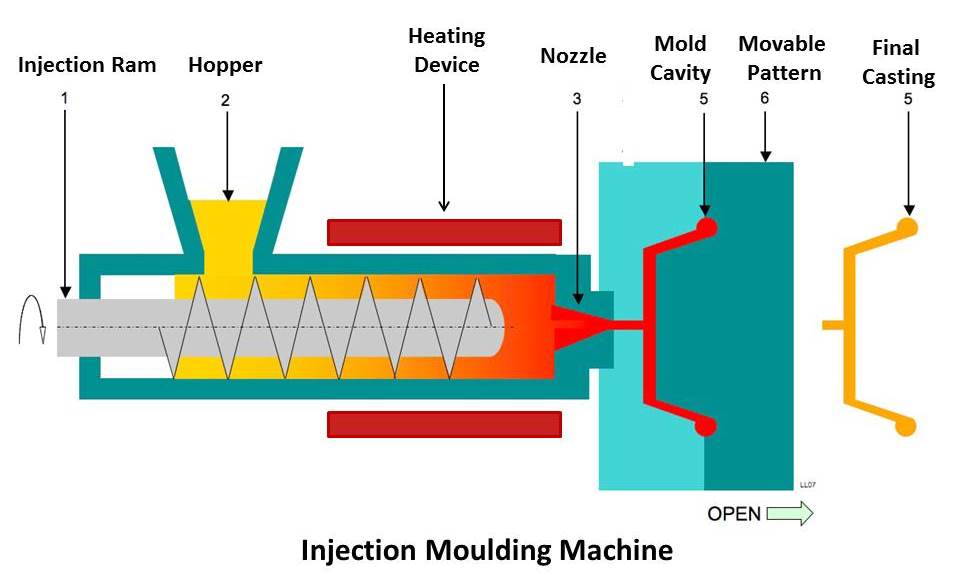

Injection Moulding Diagram

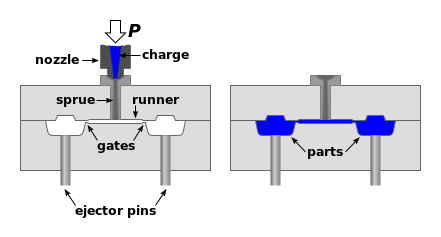

Basics of injection molding design. Flash is a molding defect that occurs when some molten plastic escapes from the mold cavity.

Compression Molding Process Injection Molding Transfer

Compression Molding Process Injection Molding Transfer

Video of injection moulding.

Injection moulding diagram. Injection moulding can be performed with a host of materials mainly including metals for which the process is called die casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. A tronicarts 3d animation which shows the injection molding process. Typical routes for escape are through the parting line or ejector pin.

The properties of the powder determine the final properties of the metal injection molded product. Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould. The finished plastic part the injection molding tool the machine the injection process and the ejection of.

The primary raw materials metal injection molding are metal powders and a thermoplastic binder. Effective solution optimally designed to best suit the automation needs of injection molding machines. Our modular product range includes hydraulic hybrid electrical and vertical injection molding technology from attractive entry level models and high precision versions to special machines for cube molds.

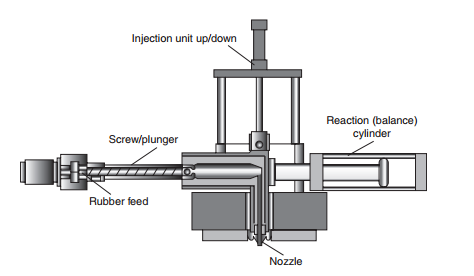

Optimize gate design to ensure adequate contact between the molten plastic and the mold. The injection molding machine consists of the injection unit and the clamping unit and their features are described below. Materials such as polystyrene nylon polypropylene and polythene can be used in a process called injection moulding.

11 injection unit 1injection capacity the proper injection capacity is found from the relationship of the molding machine capacity for the weight of 1 shot as shown in figure 11 2. Increase the size of the gate so that the injection speed becomes slower. Injection molding process data sheet injection molding process defects injection molding process description injection molding process development injection molding process diagram injection.

Allrounder injection molding machines are synonymous with quality reliability and production efficiency. Injection blow moulding box learning exercise. It is necessary to select the.

Adhering to some basic rules of injection molded part design will result in a part that in addition to being easier to manufacture and assemble will typically be much stronger in service. For letter usage and maintenance of control system detail study of this operating manual will be helpful. ¾ the limit switch and solenoids wiring must be done as per given wiring diagram.

The binder is only an intermediate processing aid and must be removed from the products after injection moulding. These are thermoplastics this means when they are heated and then pressured in a mould they can be formed into different shapes.

Injection Moulding Of Plastics

Precision Injection Molding Of Freeform Optics Advanced

Precision Injection Molding Of Freeform Optics Advanced

Injection Molding Machine Construction Working

Injection Molding Machine Construction Working

Injection Moulding Custom Injection Moulded Plastic Robinson

Injection Molding Machine Introduction Working Process

Injection Molding Machine Introduction Working Process

Rubber Injection Molding Poly Tek

Rubber Injection Molding Poly Tek

Gas Assist Injection Molding Psi Molded Plastics

Reinforced Reaction Injection Molding Rrim Closed

Injection Moulding Of Plastics

Injection Moulding Of Plastics

![]() Injection Molding Optical Liquid Silicone Rubber Simtec

Injection Molding Optical Liquid Silicone Rubber Simtec

Naturebytes Digital Making For Wildlife

Machine Wiring Diagram Catalogue Of Schemas

Injection Molding Actuation System Matlab Simulink

Injection Molding Actuation System Matlab Simulink

Basics Of Plastic Injection Mould Design

Injection Moulding Machine Mounts Controlling Excessive

Cycle Time In Injection Moulding

Injection Moulding Of Plastics

Processing Cycle Of Conventional Injection Molding Process

Processing Cycle Of Conventional Injection Molding Process

Flow Of Metal Powder Injection Molding Process Indicated

Flow Of Metal Powder Injection Molding Process Indicated

File Injection Molding Diagram Svg Wikimedia Commons

File Injection Molding Diagram Svg Wikimedia Commons

1 Injection Extrusion School Of Materials Science And

Thermal Insulation Of Injection Molding Tools An Advantage

The Plastic Injection Moulding Process If you are working on short mouldings and you are not able to get adequate shot capacity, the following tips can help. 2k injection molding

ReplyDeleteThanks for providing recent updates regarding the concern, I look forward to read more. two shot injection mold

ReplyDelete

ReplyDeletePlastic mold technology is one of the most widely used processes for producing large quantities of plastic injection mold parts. Almost everything that needs molds & molding parts, if you develop a new project then you need high-quality custom plastic mould & moulding company to support. SINCERE TECH is here to support your business. We have been a leading plastic injection mold company since 2005, have professional mould designers & mold makers to offer you the best quality and service, we use Europe & American standard mold components for all of our export molds (HASCO, DME or according to customer’s requirement), we do not only save your cost in mold making, but also excellent service & high-quality molds. We have produced plastic molds and parts for companies worldwide. We make custom molds & injection parts for various industries including food package, medical, electronics, garden, furniture, automotive, sports, containers and more, please click here to more about our mold manufacture compacity.plastic moulding

This is a very detailed post on injection molding! It seems like it covers everything from the basics like what flash is to the different types of machines and materials used. It's a bit overwhelming, but definitely a great resource for someone who wants to learn more about this process.

ReplyDelete